Temperature sensors

In many of our projects, it's necessary to measure the temperature of the surrounding air or the surface of a device. For this purpose, we can use either digital or analog temperature sensors.

An analog temperature sensor produces an analog signal that depends on the measured temperature. The measurement limits are restricted by the measurement range and the accuracy of the ADC that processes the signal from the sensor. Additionally, the number of analog inputs of the controller is usually limited, which restricts the number of sensors that can be connected simultaneously. The accuracy of the measurement is also affected by the distance between the sensor and the controller because the wire's resistance and external interference will affect the signal level. As a result, such sensors are not very common.

A more versatile option is digital temperature sensors. These sensors have their own electronic circuits with ADCs for processing the measurement results. The results are transmitted to the controller in digital form via one of the common protocols (serial interface, I2C, RS-485, etc.). Such sensors are extremely flexible in terms of selection and configuration. Depending on the required measuring range and accuracy, we can select the right sensor. In addition, we will not be limited by the controller's own ADC capabilities or the number of free inputs. When using standard protocols, tens or even hundreds of sensors located at great distances from each other can be connected to a single controller.

For simple projects, we can use sensors like DHT11, which are sufficient for determining temperatures in the home. If we need high accuracy or a wide measurement range, we can choose one of the industrial sensors. Although the cost of such sensors is higher, they work well under conditions of vibration, temperature, and other unfavorable external factors.

If we need to measure the surface temperature, we can use either a contact or non-contact sensor. The contact sensor must be attached directly to the surface being measured, as it will heat up along with it and provide the appropriate measurements. In its simplest form, it is an ordinary thermocouple made of two wires, which changes its resistance or generates current depending on the temperature. If there is no direct access to the surface of interest, or it is at a great distance or is moving, we can use a contactless sensor. Most often, this is an infrared sensor that measures thermal radiation from a surface. Since such a sensor does not heat up along with the object being measured, they can have fairly large limits of measured temperature, ranging from hundreds to thousands of degrees.

Temperature sensors can also be used as additional protection. If the device overheats above a certain limit, the protection can be triggered, and the load can be switched off. They can also be used in fire or fire detection systems.

In conclusion, temperature sensors are essential in any application project that works with real devices. Therefore, learning how to connect and use them is crucial.

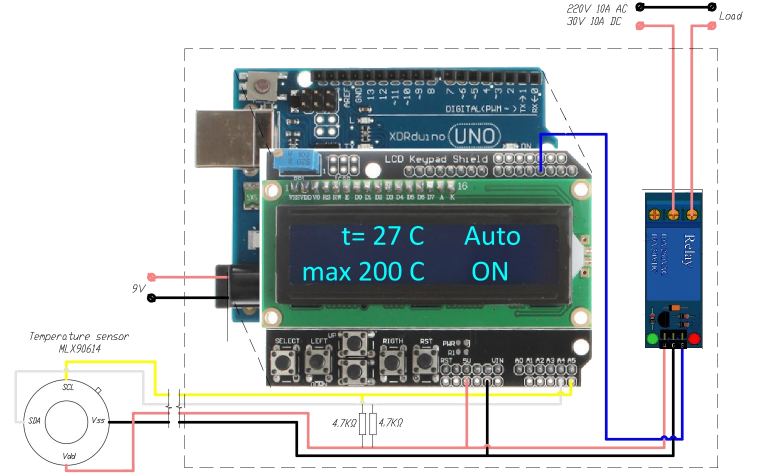

Electrical load shedding system with temperature sensor

The system is designed for emergency shutdown of electrical load based on the readings of a wireless infrared temperature sensor

The MLX90614 infrared non-contact thermometer measures the temperature of an object and transmits the data to the controller, which turns on or off the relay that controls the load

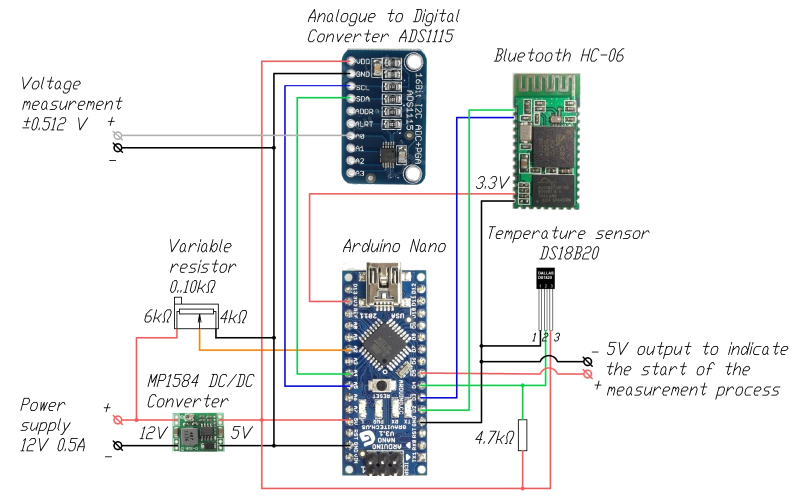

Voltage and temperature monitoring system with readings transmitted via Bluetooth

System designed for measuring voltage with high accuracy and transmitting results wirelessly to a monitoring system (PC, Mobile phone or other controller equipped with a Bluetooth receiver).

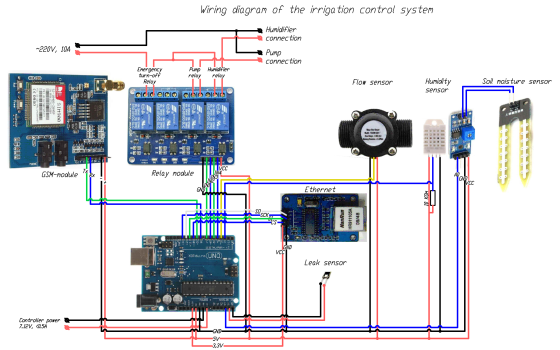

Irrigation control system

Irrigation control system for automatic maintenance of plant climate parameters using sensors, control via web interface and remote informing via mobile network

Books

Books Technology

Technology Electronics

Electronics DC motors

DC motors Raspberry Pi Controllers

Raspberry Pi Controllers Relay

Relay Temperature sensors

Temperature sensors Analog sensors

Analog sensors Digital sensors

Digital sensors ADC

ADC Bluetooth

Bluetooth Radio communication 2.4 GHz

Radio communication 2.4 GHz LCD-screen

LCD-screen All tags

All tags Programming

Programming Weaponry

Weaponry Projects

Projects