ADC

An analog-to-digital converter (ADC) is a common component in modern digital electronics. At the lowest level, all signals that travel along the conductors are analog and the ADC decrypts them and converts them into digital format. For example, if we use electronics with a voltage for logic of 5V, then the ADC determines whether a logical zero or a logical one has come to us based on the voltage on the conductor. Most ADCs are built on semiconductor transistors and do not require additional configuration.

However, if we need to determine intermediate voltage values and transmit this value in logical form, we need dedicated ADCs designed to work specifically with analog signals. They can determine the voltage level with a given accuracy and transmit the result in digital form for subsequent processing.

The main parameter of an ADC is resolution, which determines the accuracy of determining the value. The resolution parameter is specified as the bit depth, which is the number of bits necessary to store the value being measured by the ADC. For example, a 2-bit ADC can detect 4 voltage levels. If the measurement range is 5V, then this corresponds to an accuracy of 5/4 = 1.25 Volts. Each subsequent bit doubles the precision.

Standard ADCs that are built into the Arduino controller have a capacity of 10, which determines 1024 levels with an accuracy of 5/1024 = 0.0049 Volts. This is enough to connect various simple analog sensors. However, the disadvantage of these built-in ADCs is the lack of fine-tuning capabilities and a limitation on the number of simultaneously connected devices. For example, for the standard and most common Arduino controller, there are only 6 analog inputs (A0-A5). Single-board computers like Raspberry Pi do not have analog inputs.

If the ADCs built into the controller are insufficient, we can connect additional ADCs as separate devices. They can have greater accuracy (e.g. 12 bits will give us 4096 levels, 16 bits will give us 65 thousand) and often allow us to adjust both the measurement range and the required accuracy. In addition, such ADCs can have a large number of inputs, which allows us to connect dozens or even hundreds of sensors to one controller.

Of course, if we use precision ADCs, then the measurement accuracy may depend on additional factors, such as temperature and input signal quality. The ADC itself may have characteristics close to linear over the entire range of interest, or have different accuracy depending on the level of the input parameter. In any case, for each specific case, it is possible to select an ADC with the necessary parameters and not be limited by the capabilities of the built-in analog inputs.

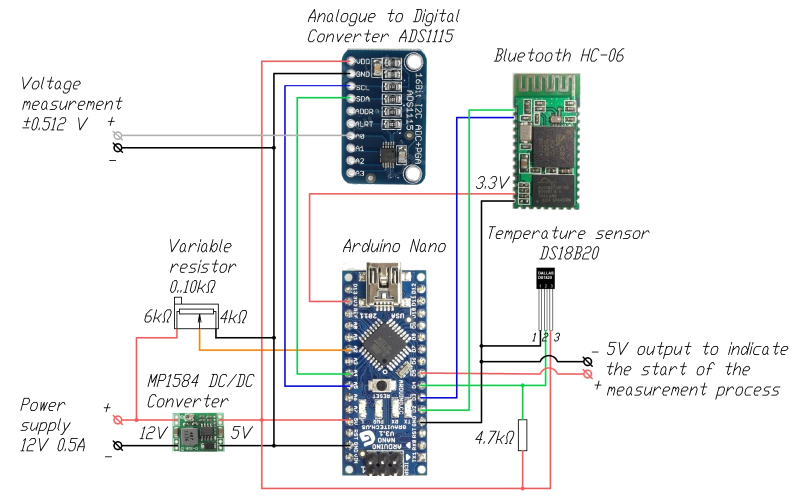

Voltage and temperature monitoring system with readings transmitted via Bluetooth

System designed for measuring voltage with high accuracy and transmitting results wirelessly to a monitoring system (PC, Mobile phone or other controller equipped with a Bluetooth receiver).

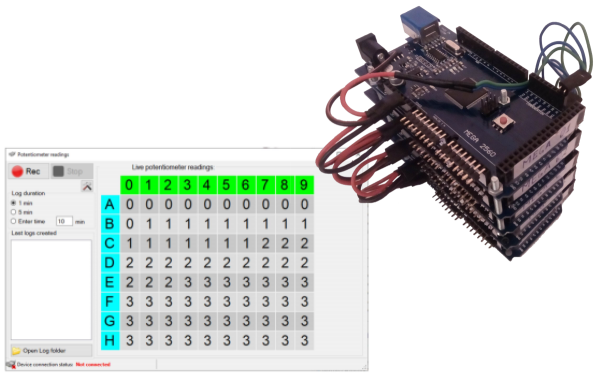

System for reading an array of analog sensors and display the results matrix

System designed to reading an array of analog sensors and display the results matrix in a convenient form (on a PC screen)

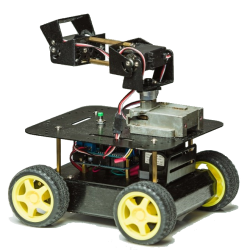

Mobile platform for testing electric motors

Mobile platform for testing electric motors. Allows you to control the movement of the platform in real time, which moves along the test route and take parameters from the sensors.

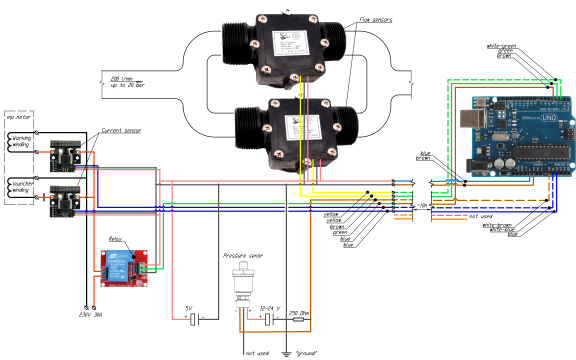

Water pumping control system

The system for installation on a pipeline for liquids pumping and control of the transportation process. Includes fluid flow sensors, motor current sensor and control relay for online control of process parameters, logging, emergency automatic and manual control of pumping.

Books

Books Technology

Technology Electronics

Electronics DC motors

DC motors Raspberry Pi Controllers

Raspberry Pi Controllers Relay

Relay Temperature sensors

Temperature sensors Analog sensors

Analog sensors Digital sensors

Digital sensors ADC

ADC Bluetooth

Bluetooth Radio communication 2.4 GHz

Radio communication 2.4 GHz LCD-screen

LCD-screen All tags

All tags Programming

Programming Weaponry

Weaponry Projects

Projects