Water pumping control system

The system for installation on a pipeline for liquids pumping and control of the transportation process

Includes fluid flow sensors, motor current sensor and control relay for online control of process parameters, logging, emergency automatic and manual control of pumping.

To process data from sensors and control the system, a separate program is used (it works on any computers with Windows OS (XP, 7, 8.10 versions)

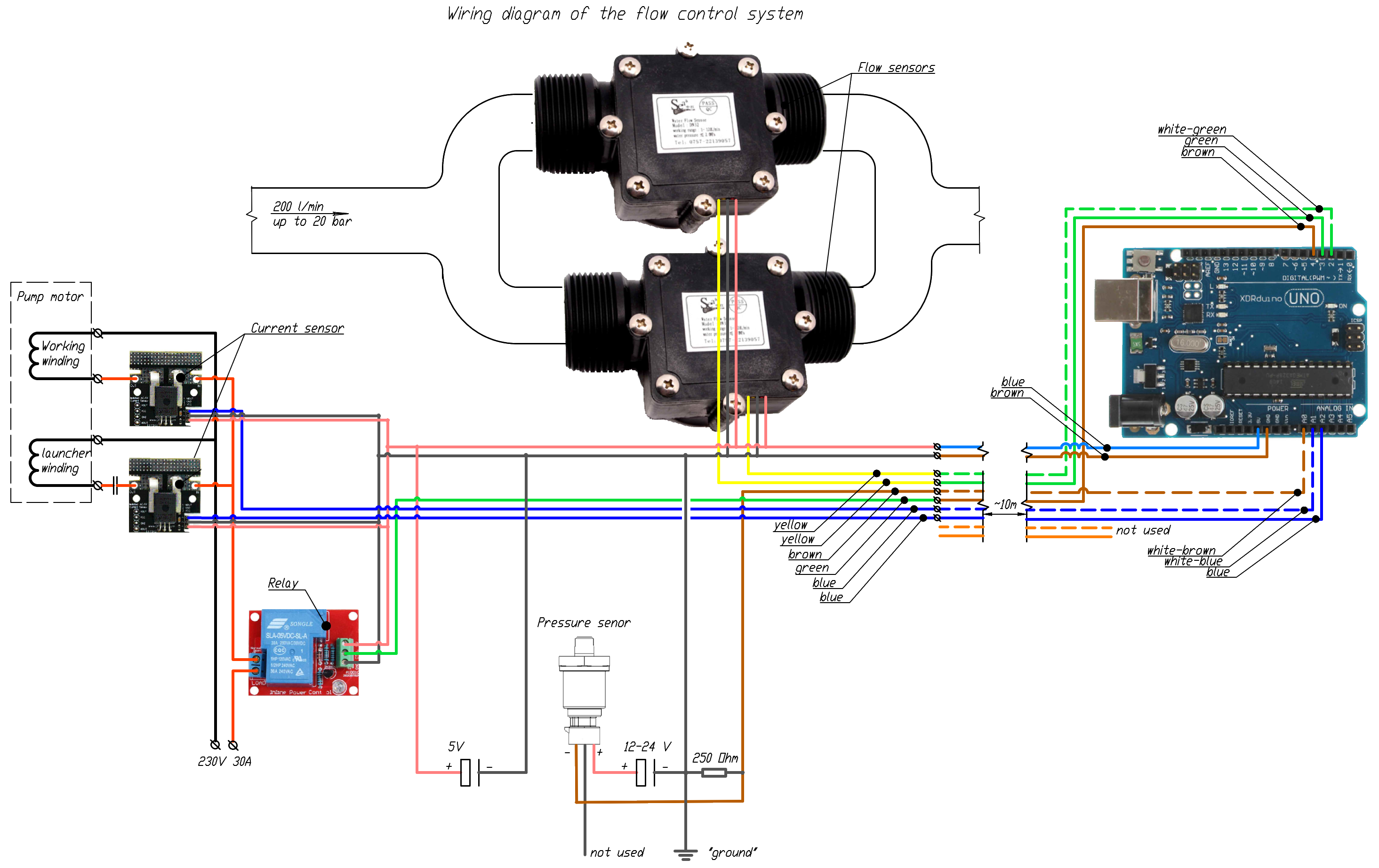

Controller and the workplace are separated from the location of the engine and sensors at a distance of 10-20m (a standard 8-wire network cable is used to transfer all data)

Functions

- Automatically turn on / off the engine

- according to a given program,

- depending on the readings of sensors

- by command from a PC.

- Data can be transferred to PC via USB cable.

- Processing data from sensors and control pump engine via desktop application (Microsoft Windows compatible)

- Logging of process (with saving of logs and opening previously opened data)

Main system parameters:

- Nominal water consumption – 200 l/min (two flows 100 l/min each)

- Maximal water consumption – 240 l/min

- Working temperature – 0..80 °C

- Working moisture – 35%..90% RH

- Liquid temperature – 0..120 °C

- Nominal pressure – 20 bar

- Peak current on the motor windings – 50 А (each winding)

- Pump motor voltage – up to 230V

- Pump motor current – up to 30A

Flow control application

Desktop application for work of engraving machine. Developed on C++ using .Net framework.

Can work on any PC with operating system supporting .NET framework (windows 7,10,11)

Flow control system cotrol application. Version 1.01

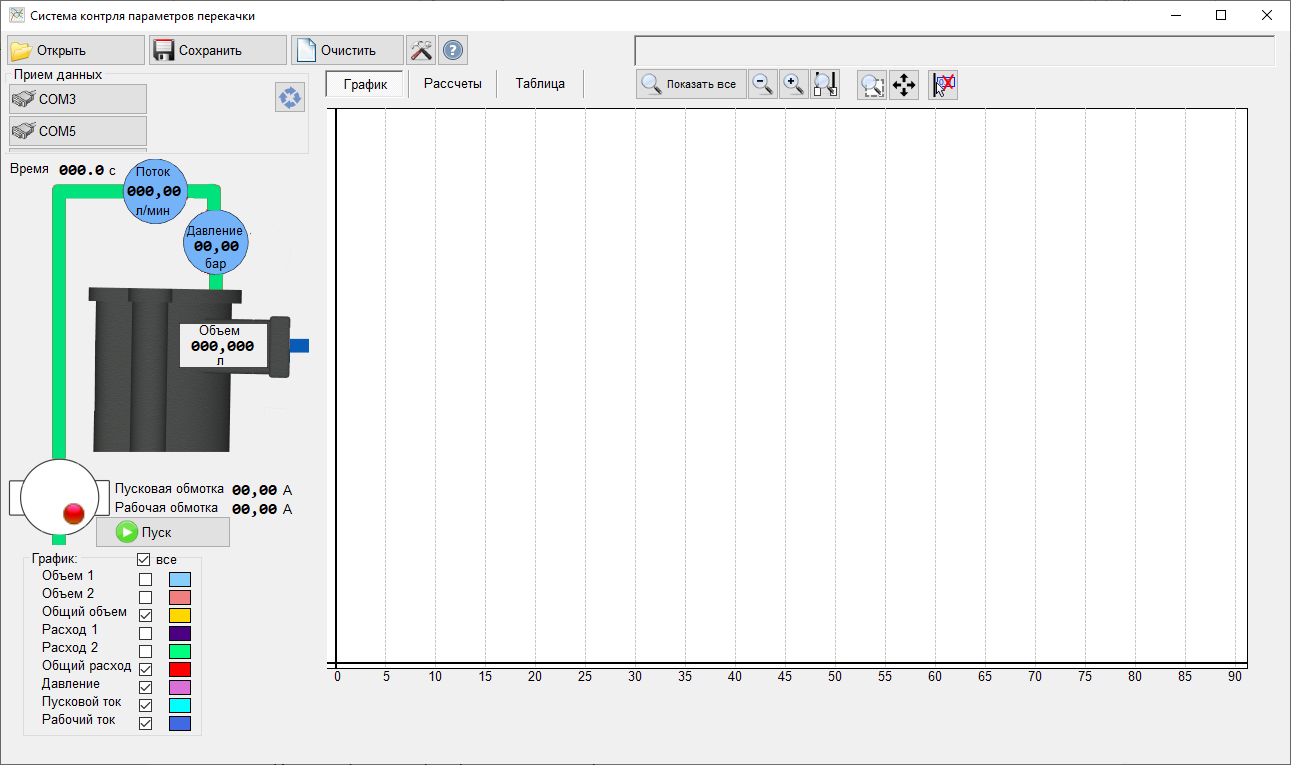

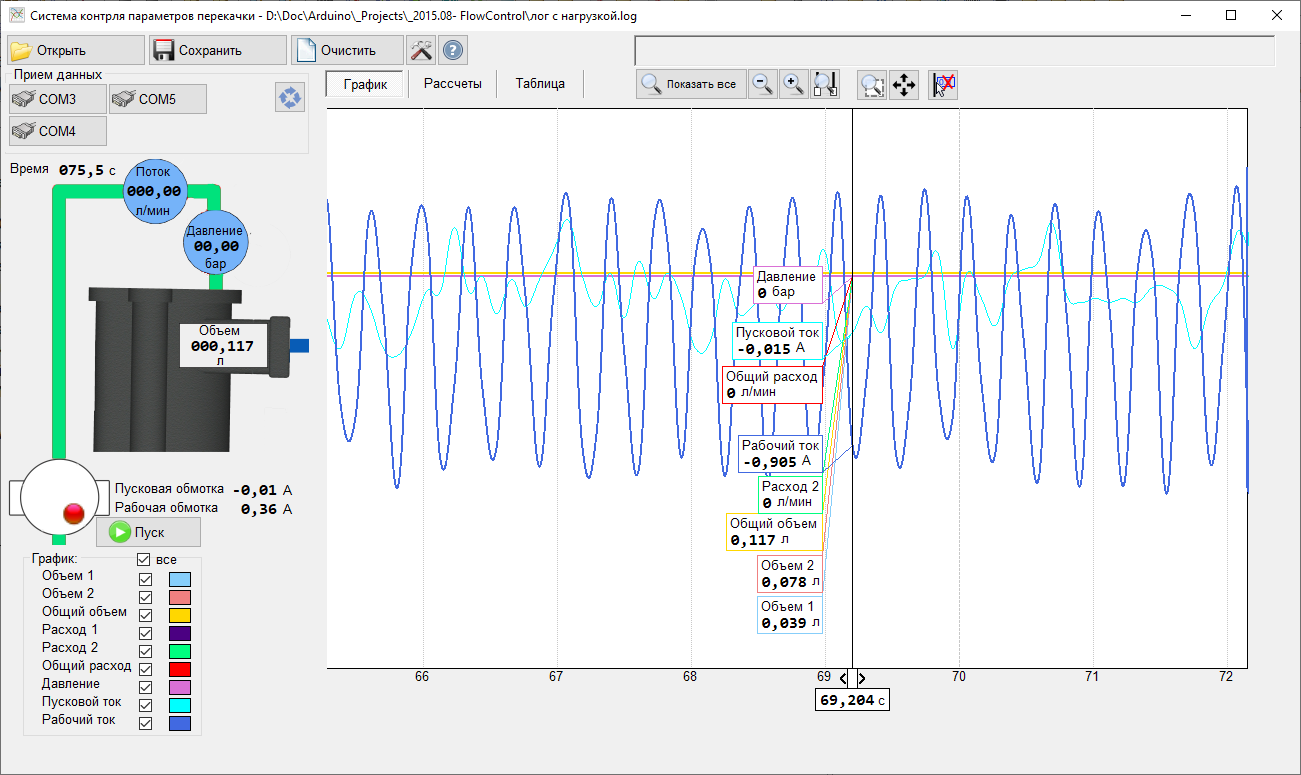

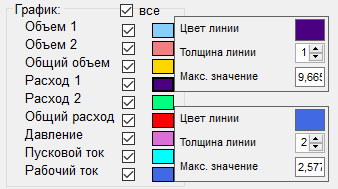

The main window contains a mnemonic diagram with sensor values and control buttons. In the central panel, all values can be displayed in graphical or tabular form.

The buttons in the top row are used to zoom (you can also use the scroll wheel), reset the zoom (double click the middle mouse button), move the field of view on the chart (you can use the middle mouse button), show the slider with the current values.

An independent setting of the line display style for each parameter can be applied using the panel on the left side of the window.

The main menu includes buttons to save and open previously saved logs, system parameters, and a console with current commands sent to the controller and received responses.

A separate panel is designed to select the port to which the controller will be connected.

Main functions of flow control application:

Real-time acquisition of the following data:

- Consumption of liquid flowing through the pipeline (by independent pipelines and total)

- Amount of liquid pumped over a certain period of time

- Pump motor current (for working and starting winding)

- Liquid pressure value

Engine control - manual or automatic on/off

Keeping a log of all received data

- Logging frequency up to 20 polls / sec in text form

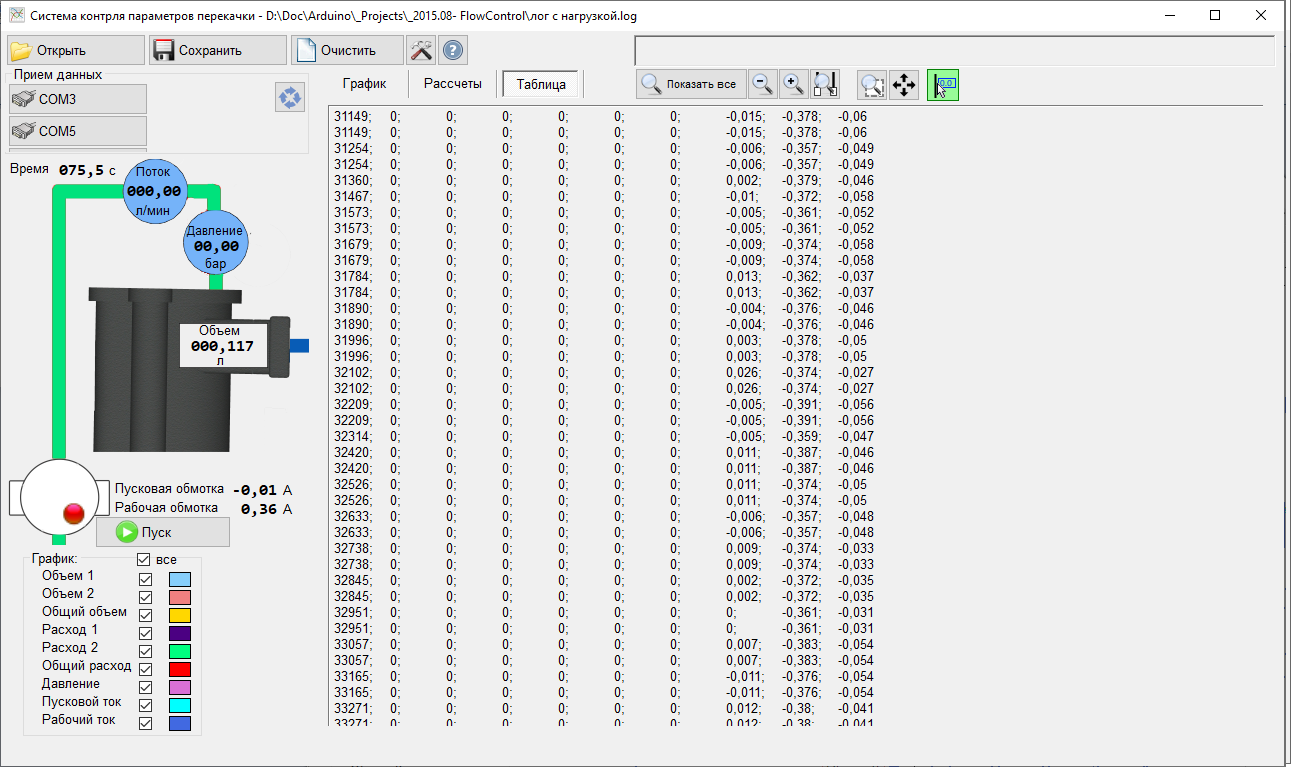

- Log output in text format

- Log output in the form of a graph with the ability to scale, disable the display of unnecessary data, arithmetic calculations.

- Saving a log of sensor readings in text form for subsequent use in calculations (Excel, mathematical packages MatCAD, MatLab)

- Opening previously opened logs with the ability to plot graphs and operations on them

Application settings:

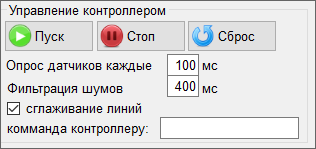

- Manual start, stop and reset of controller

- Change of sensors frequency

- Change noise filtering strength (approximation of several sensor readings in a certain period of time to avoid random peaks and dips in values)

- Smoothing lines on graphs

- Manual sending command to controller and receiving answer

Display parameters for graphical values (independently for each parameter):

- Enabling the display of each parameter

- Change color and thickness of line

- Change vertical scale to fit in window

Components

- Controller Arduino UNO

- G1'1/4 water flow sensor (based on Hall sensor) – 2 pcs

- Current sensor ACS758 – 2 pcs

- Pressure sensor MLH025BSB01B

- Relay module (30А 240VAC)

Wiring diagram

Possible further improvements

-

Remote connection (via Bluetooth, IR or radio channel)

-

automatic control according to various patterns, including emergency shutdown upon reaching the critical values of the parameters.

-

Web interface for remote connection

-

SMS informing and control using GSM module.

-

Smooth change of engine operation parameters incl. smooth start.

-

Control program usability improvements

Books

Books Technology

Technology Electronics

Electronics DC motors

DC motors Raspberry Pi Controllers

Raspberry Pi Controllers Relay

Relay Temperature sensors

Temperature sensors Analog sensors

Analog sensors Digital sensors

Digital sensors ADC

ADC Bluetooth

Bluetooth Radio communication 2.4 GHz

Radio communication 2.4 GHz LCD-screen

LCD-screen All tags

All tags Programming

Programming Web-interface

Web-interface Graphical interface

Graphical interface Windowed Application

Windowed Application Video

Video Images

Images Audio

Audio Text

Text HTML

HTML Lof-files

Lof-files Neural networks

Neural networks Weaponry

Weaponry Projects

Projects